Rubber latches are used for securing doors, panels, and enclosures in various applications. However, like any mechanical component, rubber latches can experience wear and tear over time, leading to potential failure. This article explores signs of a failing rubber latch, maintenance techniques, indications for replacement, and the appropriate rubber latches for specific applications. Read More…

Hardware Mfg. supplies stock inventory parts in addition to creating custom components for OEM and resellers. We work with a number of different industries such as agriculture, drug tablet, livestock, truck equipment, conveyors, and more.

Specializing in custom-made hinges is what Hinge & Hardware is known for. We also stock certain types of standard models to round out the availability for our customers. The aforementioned are available as mild steel, aluminum and stainless. We also have a wider hardware line that includes door seals, gaskets, handles, a variety of latches and enclosure hardware.

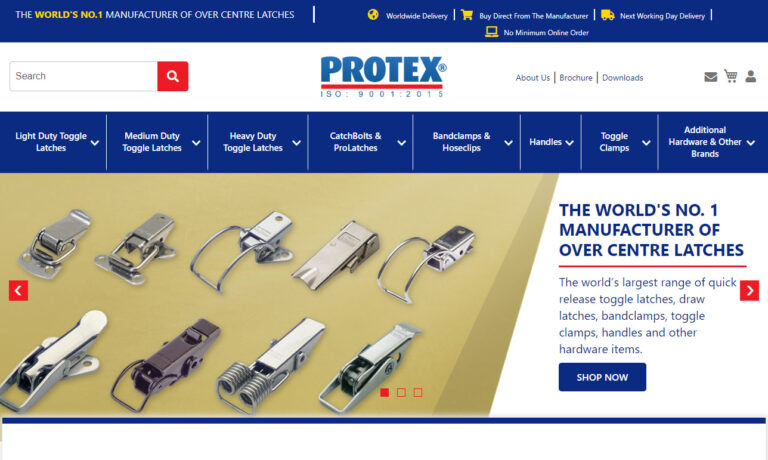

At PROTEX® we offer light to heavy-duty fasteners, handles, flush latches, case fittings, bandclamps, catch plates and more. We manufacture a large range of over centre fasteners often known as draw latches/toggle clamps/catches/over centre toggle fasteners.

Cabinet latches are our specialty! We are located in Torrington, CT but we are committed to serving our customers wherever they may need us! All of our products go through extensive and intensive testing to ensure that we are providing our customers with only the best possible products. For more information on what we can do for you visit our website today or get in touch via email or telephone!

If your product application requires the finest in engineered latches, then TriMark has the solution for you. Choose from single or multi-rotor, compression, deadbolt, sliding bolt, slam action, pin type and more, all made to the highest standards to meet your expectations. Trust TriMark’s more than 50 years of expertise and earned reputation for quality latches, hinges, handles, locks and keys

More Rubber Latch Manufacturers

Maintaining Rubber Latches

There are several signs that indicate a rubber latch may be failing. One common sign is difficulty in opening or closing the latch, indicating decreased effectiveness or misalignment. Excessive wear on the rubber surface or signs of degradation, such as cracking or brittleness, are also indications of a failing latch. If the latch fails to securely hold objects or consistently comes loose, it may be time for maintenance or replacement. Regular inspection is crucial in identifying these signs early on and preventing further damage or potential accidents.

Proactive maintenance can help address minor issues and prolong the lifespan of rubber latches. One simple maintenance technique is regular cleaning using mild soap and water to remove dirt, dust, or debris that may interfere with latch performance. Lubricating the latch mechanism with a silicone-based lubricant can similarly improve its functionality and ensure smooth operation. Additionally, inspecting and tightening any loose screws or mounting hardware associated with the latch can help maintain its stability and effectiveness.

Replacing Rubber Latches

There are instances where maintenance may not be sufficient, and a rubber latch requires replacement. If the latch has undergone extensive damage, such as severe cracks or complete breakdown of the rubber material, replacement is necessary. Additionally, if the latch no longer provides a secure closure, jeopardizing the safety of the latched objects, replacement is crucial. Furthermore, if the latch no longer meets the functional requirements of the application, such as changes in load capacity or environmental conditions, selecting a new latch that better suits these requirements becomes essential.

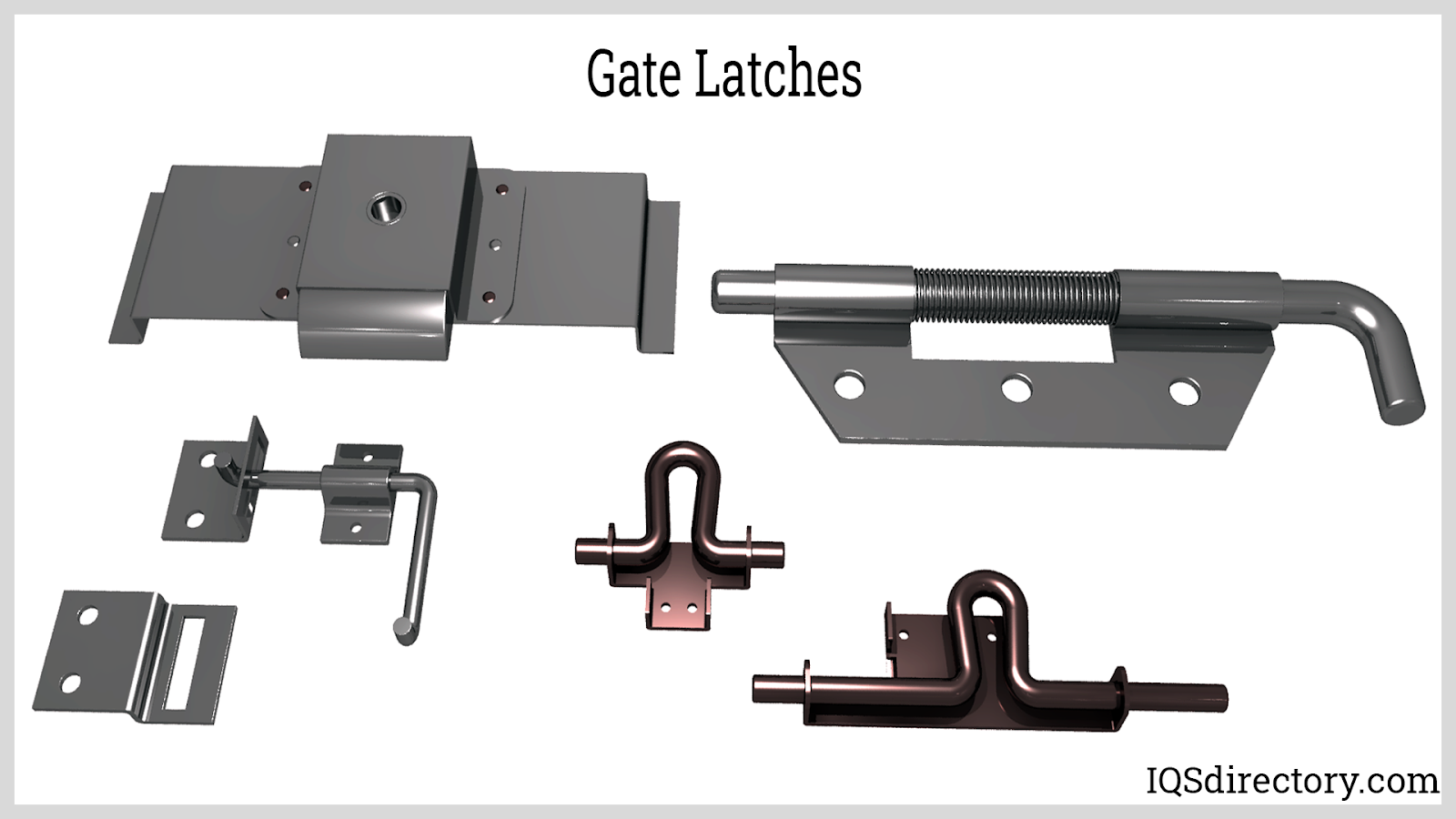

Choosing a Rubber Latch

Choosing the right rubber latch for a specific application is crucial to ensure optimal performance and longevity. It is essential to consider factors such as the required load capacity, environmental conditions, and installation requirements. Consulting with a supplier or manufacturer of rubber latches is highly recommended to determine the most suitable latch based on these factors. Providing them with detailed information about the application, including the type of enclosure, expected usage, and any specific operational demands, will help in selecting the appropriate latch for the intended purpose.

Selecting an inappropriate rubber latch for an application can lead to various consequences. If a latch is not adequately designed to handle the required load capacity, for example, it may fail under stress, compromising the security and safety of the latched objects. As a result, it is vital to consider the specific demands of the application to prevent these consequences and ensure reliable closure solutions. Meanwhile, incompatibility with environmental conditions, such as exposure to extreme temperatures, chemicals, or moisture, can result in accelerated wear and deterioration of the latch, leading to premature failure.

Finding a Rubber Latch Manufacturer

Consider factors such as their experience, product range, manufacturing capabilities, and certifications. Contact each supplier to discuss your specific requirements and assess their responsiveness, technical knowledge, and willingness to offer personalized solutions. Request samples or catalogs to evaluate the quality of their rubber latches. Furthermore, inquire about their warranty policies, lead times, and pricing to ensure they align with your needs and budget. Ultimately, choosing a supplier or manufacturer with a strong reputation, reliable products, and exceptional customer support will ensure a smooth and successful collaboration.

Choosing the Right Rubber Latch Company

To ensure the best result when purchasing rubber latches, compare several companies using our directory of rubber latch companies. Each rubber latch manufacturer has a business profile page highlighting areas of experience and capabilities. Each profile has a contact form to directly communicate with the company for more information or to request a quote. Review each company’s website using our patented website previewer to quickly learn each company’s specialty. Then, use our simple RFQ form to contact multiple rubber latch companies with the same form.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services