A two-part latch called a “draw latch” contains an arm on one side that may connect to the other half; as it closes, the clasp draws the two sides together. Draw latches hold two components firmly together temporarily until they are driven apart by a wedge, wing nut, or hand. They operate like an ordinary hinge that can be pulled open by hand and employs tension to retain two things tightly connected—frequently applied to windows, toolboxes, chests, and crates. Read More…

Hardware Mfg. supplies stock inventory parts in addition to creating custom components for OEM and resellers. We work with a number of different industries such as agriculture, drug tablet, livestock, truck equipment, conveyors, and more.

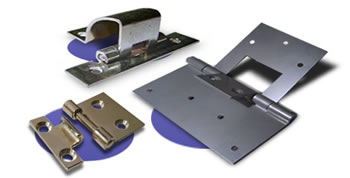

Specializing in custom-made hinges is what Hinge & Hardware is known for. We also stock certain types of standard models to round out the availability for our customers. The aforementioned are available as mild steel, aluminum and stainless. We also have a wider hardware line that includes door seals, gaskets, handles, a variety of latches and enclosure hardware.

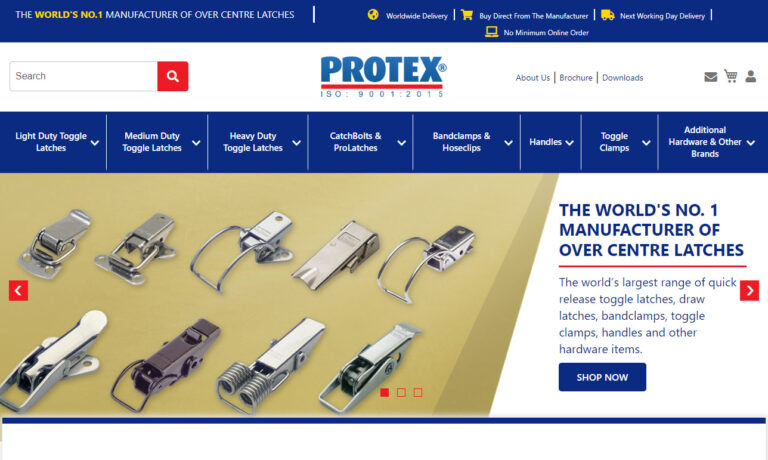

At PROTEX® we offer light to heavy-duty fasteners, handles, flush latches, case fittings, bandclamps, catch plates and more. We manufacture a large range of over centre fasteners often known as draw latches/toggle clamps/catches/over centre toggle fasteners.

Cabinet latches are our specialty! We are located in Torrington, CT but we are committed to serving our customers wherever they may need us! All of our products go through extensive and intensive testing to ensure that we are providing our customers with only the best possible products. For more information on what we can do for you visit our website today or get in touch via email or telephone!

If your product application requires the finest in engineered latches, then TriMark has the solution for you. Choose from single or multi-rotor, compression, deadbolt, sliding bolt, slam action, pin type and more, all made to the highest standards to meet your expectations. Trust TriMark’s more than 50 years of expertise and earned reputation for quality latches, hinges, handles, locks and keys

More Draw Latch Manufacturers

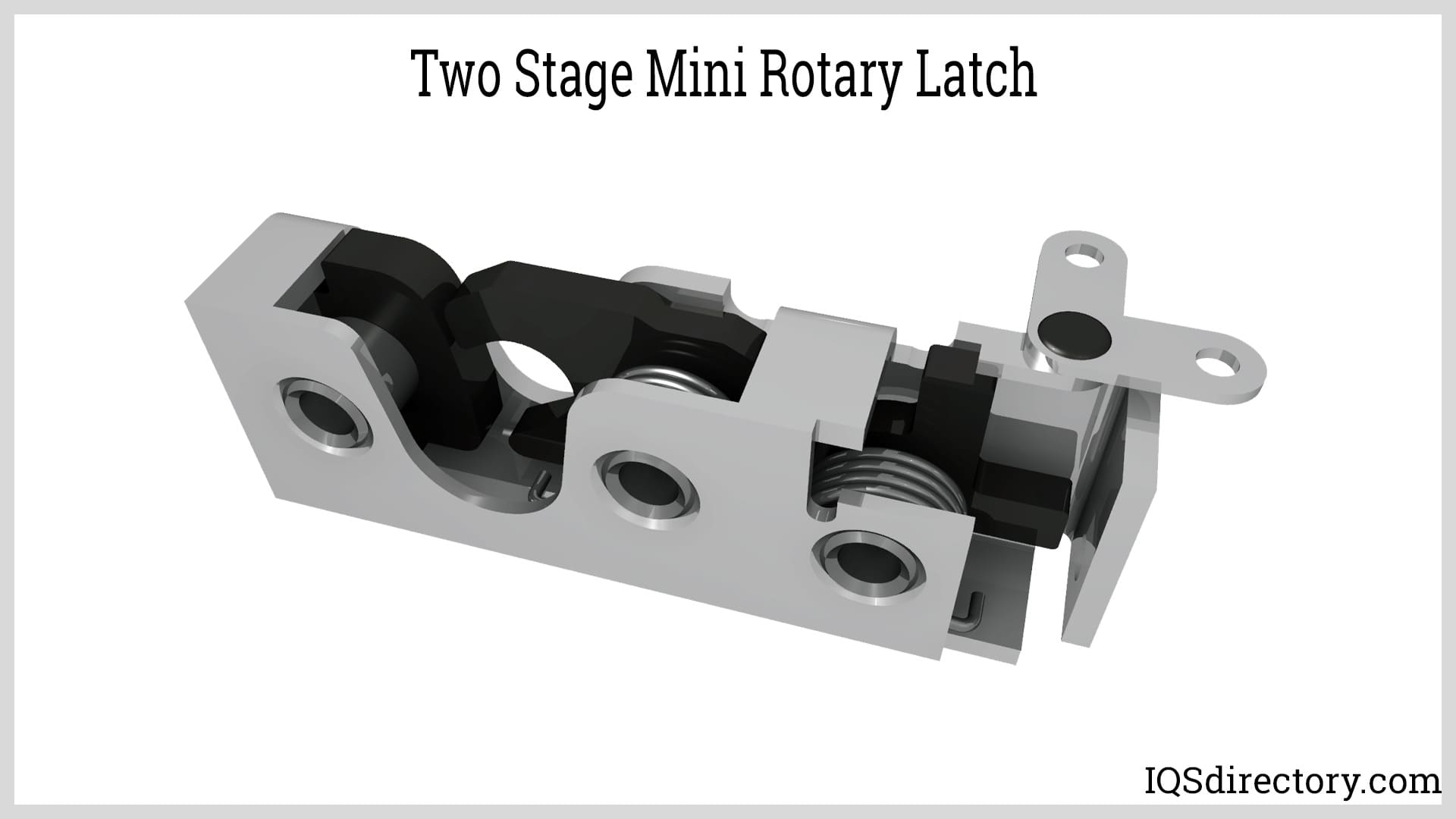

Any door can have its draw latches changed to fit it and have a push-pull mechanism that can be opened with little effort while snugly secured when the user is not holding it. Some types also come with hinges. Because of how they work, they are often referred to as "toggle clamps" or "over-center fasteners." Depending on their intended application, they also come in various sizes and forms. Nevertheless, all draw latches share a few design elements that make them easy to install without additional equipment.

Working Principle of a Draw Latch

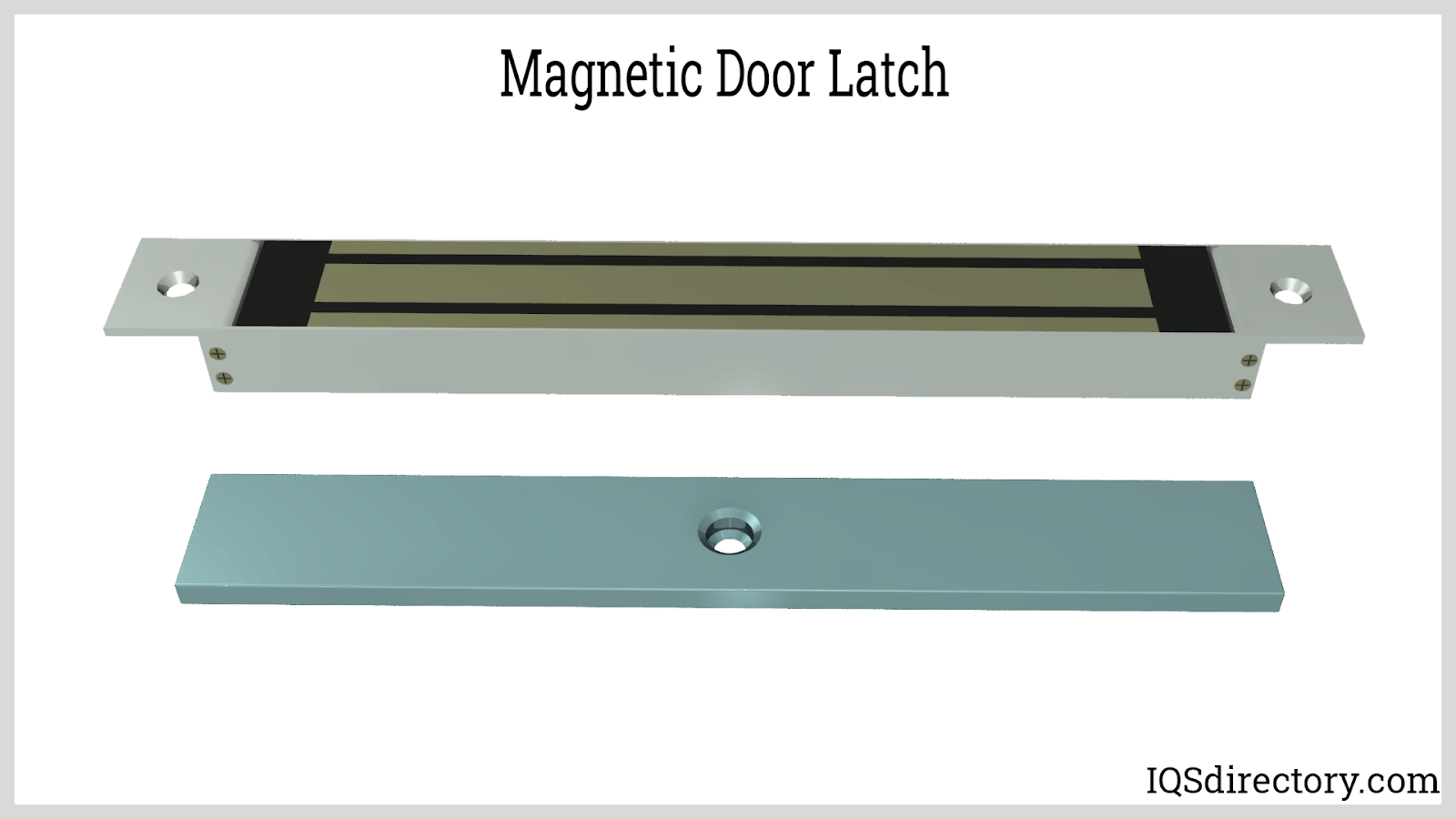

Draw latches can be accessed from either side of the door. In draw latches, the blade and keeper are the two basic components that, when drawn together, produce tension. The keeper is a hooked plate that links to the blade, and the blade is a tiny plate. These two objects are tightly joined together by a hinge between them. Draw latches, which can be secured or unlocked with a single pull of the handle, offer additional security.

Depending on the purpose, the installation may be horizontal or vertical. It can also be used successfully on paint, zinc, steel, and padlocks, among other materials. In addition, draw latches can lessen machine noise and vibration when applied properly.

Types of Draw Latches

Draw latches can be any of the following sorts, each of which has a variety of sizes and shapes:

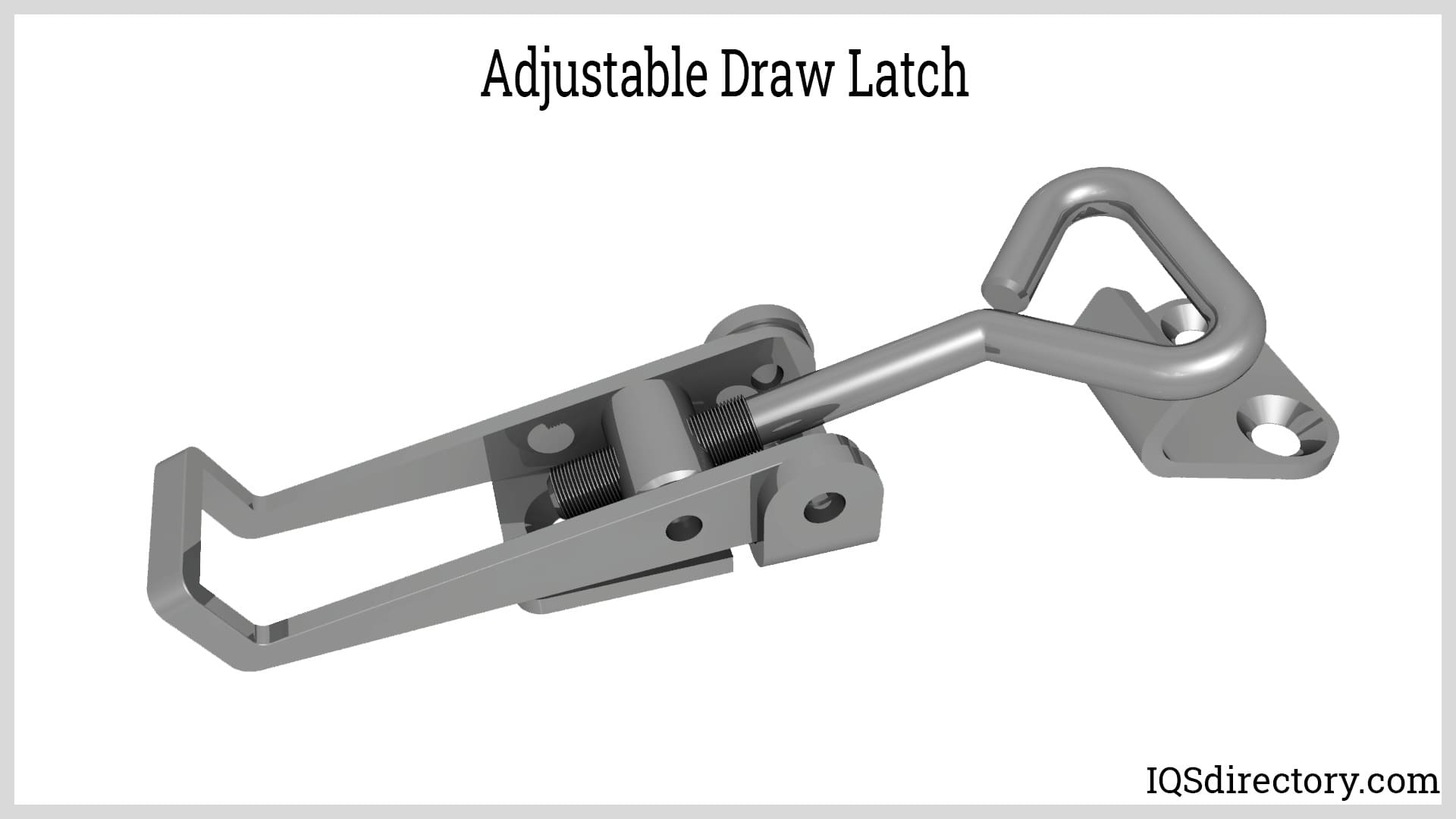

Adjustable Draw Latches

The arm of adjustable draw latches is rotated around its hinge pin and then secured by a bolt or screw to modify the tension based on the application.

Under-Center Draw Latches

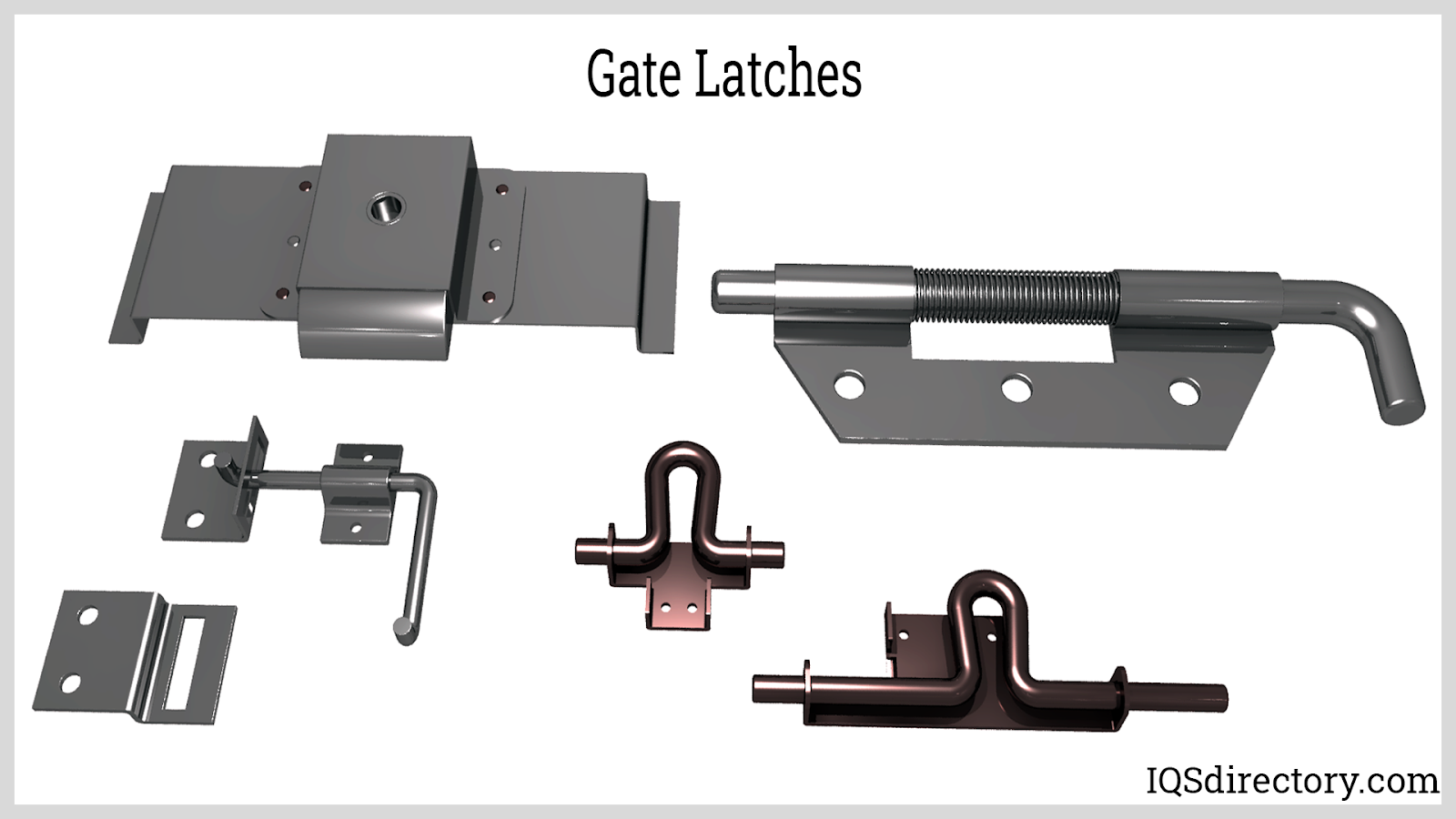

Under-center draw latches are frequently employed where latching occurs out of a plane. The gate can be kept from opening accidentally by using its hook keeper. After the latch has been positioned on its hinge, the keeper is always fastened by either welding, riveting, or bolting it in place. A full rotation in either direction can only open the latch center; it will not open unless its keeper is released from one or both sides.

Over-Center Draw Latches

Over-center draw latches are frequently employed for gates that must open perpendicular to their hinges. This style of draw latch has a pull handle attached to the middle, allowing it to be opened while keeping its gate closed and secure when not in use. Each side's top is where the hinge pin is located, and it can be welded in after installation.

Concealed Draw Latches

This draw latch is frequently employed when a design calls for concealing the latching mechanism. These concealed draw latches are mounted inside panels that are butted together and use tool actuation to draw the panels together gradually. It has a rotating arm with an enclosed center that can be extended outwards by its draw handle, allowing for simple access, and a metal hook on one side. The hook keeper stops the arm from being mistakenly unlatched if it is pulled out too far.

Pull Draw Latches

A pull draw latch is frequently used when latching happens out of the plane. This kind of draw latch's arm is hoisted into position by a handle attached at one end, and it is then fastened using a hook keeper on the other side to prevent accidental opening.

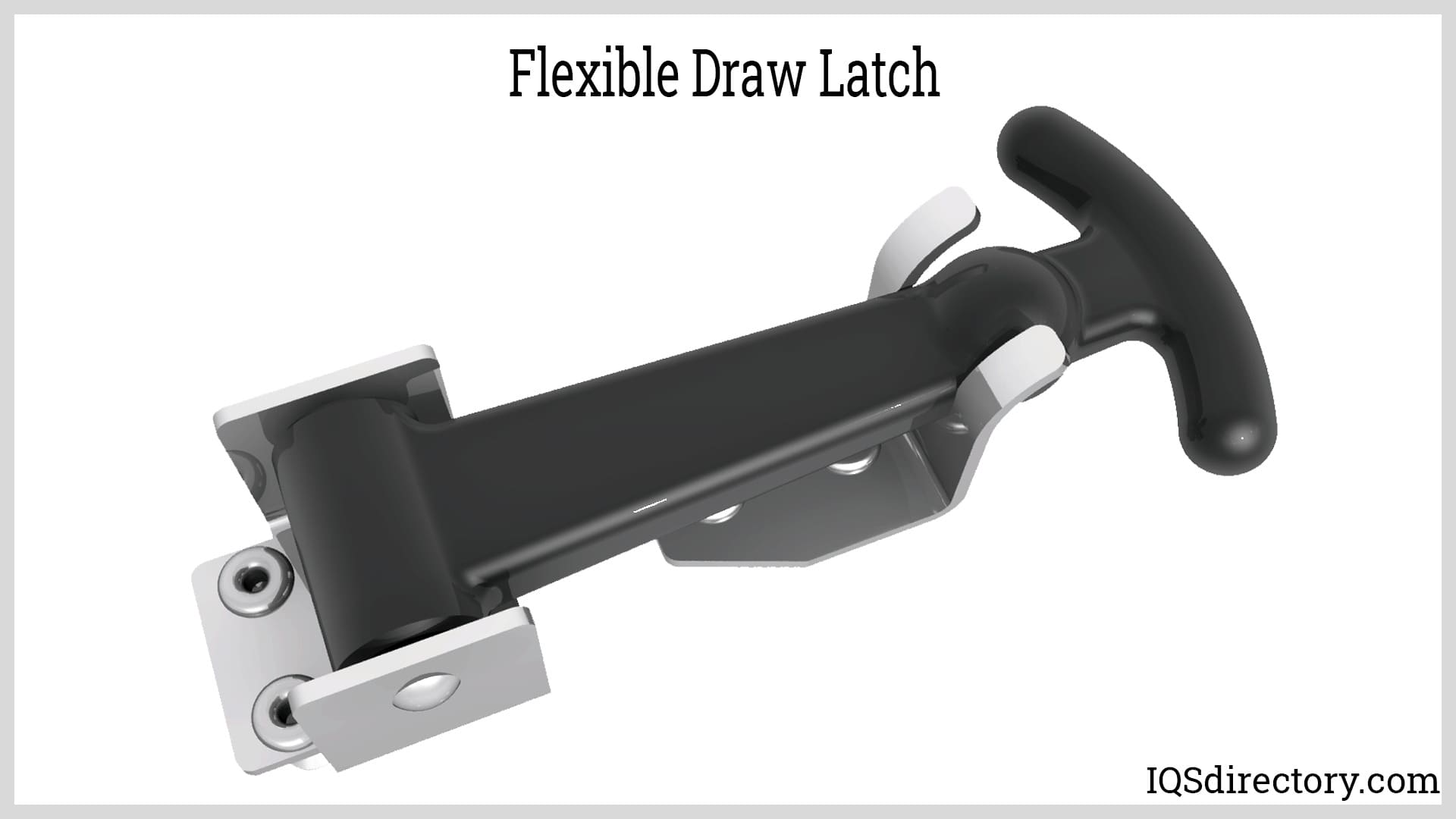

Flexible Draw Latches

A flexible metal band on this style of draw latch can be readily extended over the hook keeper on either side. This draw latch will securely lock into place when tension is applied. The gate can only be opened by simultaneously disengaging both hooks with one hand, pulling outward until they are entirely released, and then manually lifting the gate.

Applications of Draw Latches

Draw latches are used in various industries, some of which are listed below.

HVAC Systems

In HVAC systems, draw latches are frequently used to fasten large parts like the furnace, compressor, and condenser. Draw latches can also be fastened to a cabinet that houses controls or other electrical equipment. In this way, they guard against unauthorized individuals interfering with the wire while permitting simple access when required.

Storage Compartments and Lids

Draw latches can hold lids or storage compartments onto other containers like toolboxes and ammunition boxes.

Exhibits and Displays

Draw latches can secure the backing panels to furniture pieces, among other exhibits and displays. Draw latches are frequently seen in museums, where they are used to join pieces of foam core or hardboard. They offer support and protection while also preventing tampering with the wiring that has already been installed inside of these pieces.

Lawn and Garden Equipment

Draw latches are also utilized on lawn and garden equipment, with enclosure security being its primary application. Greenhouses and other structures that host plants or animals can have draw latches attached to the corners.

Advantages of Draw Latches

- Simple to specify and easy to install

- The mechanical advantage of compressing gaskets and ensuring sealing

- Materials and finishes suit any environment

- Draws panels together and holds them securely

- Alternatives are available for a wide range of sizes and strengths.

Disadvantages of Draw Latches

- They are easy to manipulate.

- They require regular maintenance.

Choosing the Proper Draw Latch Manufacturer

To ensure you have the most productive outcome when purchasing draw latches from a draw latch manufacturer, it is important to compare several companies using our directory of draw latch manufacturers. Each draw latch manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each draw latch business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple draw latch companies with the same form.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services