Latches are a type of mechanical industrial hardware used to fasten doors, windows, cabinets and other such items that can be either open or closed. Read More…

Hardware Mfg. supplies stock inventory parts in addition to creating custom components for OEM and resellers. We work with a number of different industries such as agriculture, drug tablet, livestock, truck equipment, conveyors, and more.

Specializing in custom-made hinges is what Hinge & Hardware is known for. We also stock certain types of standard models to round out the availability for our customers. The aforementioned are available as mild steel, aluminum and stainless. We also have a wider hardware line that includes door seals, gaskets, handles, a variety of latches and enclosure hardware.

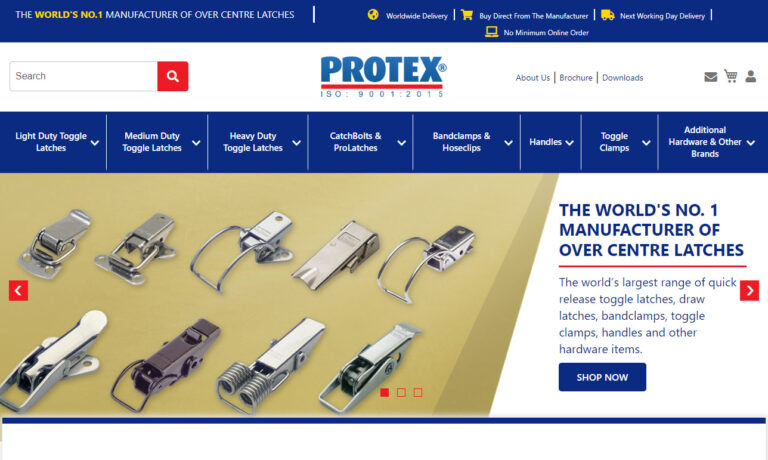

At PROTEX® we offer light to heavy-duty fasteners, handles, flush latches, case fittings, bandclamps, catch plates and more. We manufacture a large range of over centre fasteners often known as draw latches/toggle clamps/catches/over centre toggle fasteners.

Cabinet latches are our specialty! We are located in Torrington, CT but we are committed to serving our customers wherever they may need us! All of our products go through extensive and intensive testing to ensure that we are providing our customers with only the best possible products. For more information on what we can do for you visit our website today or get in touch via email or telephone!

If your product application requires the finest in engineered latches, then TriMark has the solution for you. Choose from single or multi-rotor, compression, deadbolt, sliding bolt, slam action, pin type and more, all made to the highest standards to meet your expectations. Trust TriMark’s more than 50 years of expertise and earned reputation for quality latches, hinges, handles, locks and keys

More Latch Manufacturers

What Are Latches and What Are They Used For?

Latches are essential mechanical fixtures designed to temporarily secure surfaces together. They serve various purposes, such as keeping doors, cabinets, and gates closed securely. In industrial settings, robust latches play crucial roles in refrigeration systems, storage facilities, utility boxes, and vehicles like trucks and trailers. Typically, these latches are crafted from assembled or welded die-cast, stamped, or forged metals for durability and reliability.

Latch Applications

Latches serve their primary purpose in securely closing and releasing two adjacent surfaces. They are designed for specific functions like door, cabinet, gate, and paddle latching across various industries including furniture, construction, transportation, security, and home improvement.

The History of Latches

Latches have a long history, dating back to ancient times as one of the earliest forms of modern hardware. Some of the oldest surviving examples originate from 13th-century Western Europe and China.

Among the enduring types are the Suffolk latch, developed in 16th-century England, and the Norfolk latch, from 19th-century England. Though they aren’t particularly robust or secure, they continue to be utilized today primarily for decorative or whimsical purposes.

Since their inception, latches have reliably secured doors shut without the ability to lock them, a task historically reserved for bolts. However, modern advancements have introduced latches that can now both fasten and lock doors. Innovations such as electric strike plates, springs, magnetism, and other technologies have further transformed door security.

Latch Design

Production Process

Manufacturers use die casting, stamping, or forging methods to fabricate latches, depending on the design. They may also incorporate additional components through assembly or spot-welding as required.

Materials

Choosing the right material is crucial for latch types. Metals, known for their durability and resistance to impact, are often preferred. Heavy-duty latches, designed for frequent and high-stress applications, are typically crafted from various types of metals to ensure longevity and reliability under demanding conditions.

Stainless steel, steel, aluminum alloy, cast iron, and brass are frequently chosen materials for crafting sturdy, enduring latches. Incorporating thermoplastics in latch production enhances flexibility and significantly boosts shock and impact resistance. Unlike metals, plastics excel in absorbing vibrations, adding an extra layer of durability to the latches.

Considerations and Customization

When manufacturers choose or create a custom latch for a customer, they must consider several design factors: the material used, the mounting design, and the latching position. The performance of an industrial hardware latch depends on specific usage requirements, such as applied force, operational frequency, and exposure to environmental conditions and weather.

Mounting Design

When choosing a latch type, manufacturers consider both the intended use and the space available on the mounting surface. Certain surfaces are better suited for heavy-duty latches, so it’s crucial that the latch mechanism isn’t overly bulky or heavy for the mounting surface. Various mounting options exist for latches.

Concealed mounting involves hiding the latches and their mounting hardware behind the panel.

Edge mounting positions the latch components along the edge of the mating panels, whereas face mounting involves mounting the latches directly onto the front surface of the panel.

Side mounting involves positioning both the latch and the keeper on the rear of the connecting panels, hidden from view on the cabinet or door front.

In contrast, single-hole mounting entails installing the latch within a single hole on the panel’s face.

Latching Position

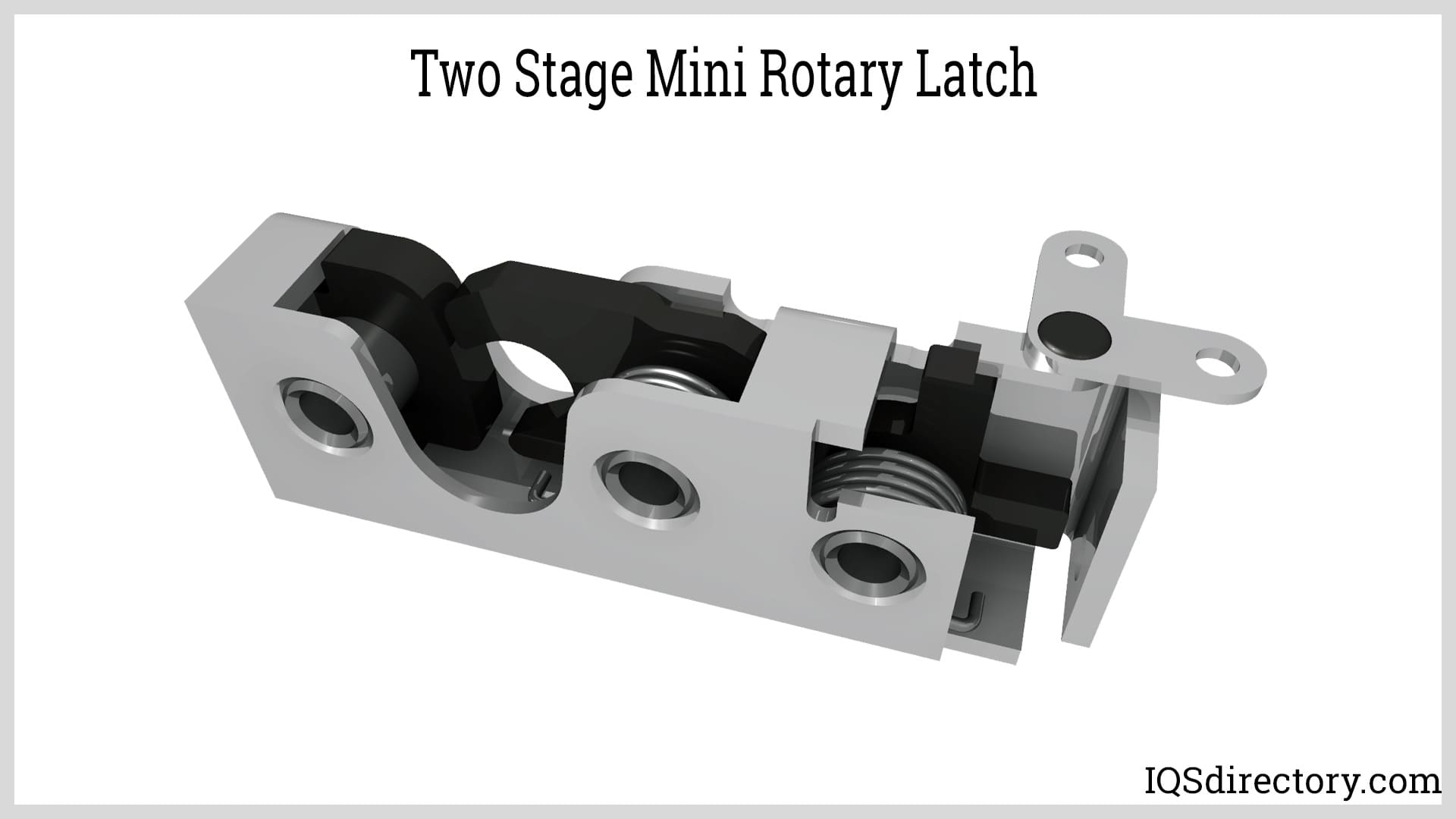

The positioning of the latch is crucial. A primary latching position ensures the door is firmly closed, whereas a secondary latching position keeps the door secured but not fully closed.

Latch Features

Most latches typically involve plates or brackets positioned on two adjoining surfaces. One bracket secures a pin or post, while the other holds a notch, groove, or seal into which the pin fits snugly. When the pin is inserted between the brackets of the latch, it prevents the door, cabinet, gate, or lid from being opened.

Types of Latches

Latches are employed across diverse contexts, requiring a wide array of industrial design types and capabilities. Some are named after the materials they’re made from, others after the objects or mechanisms they secure, and still more after their components or operational methods.

Stainless steel latches provide robust strength and excellent resistance to corrosion, making them ideal for applications exposed to moisture and frequent use.

Plastic latches, crafted from robust thermoplastics, offer a lightweight and customizable latching solution. They can be easily fabricated to suit specific designs and requirements. Additionally, various alternatives such as compression latches, draw latches, bolt latches, spring latches, and slam latches are also available.

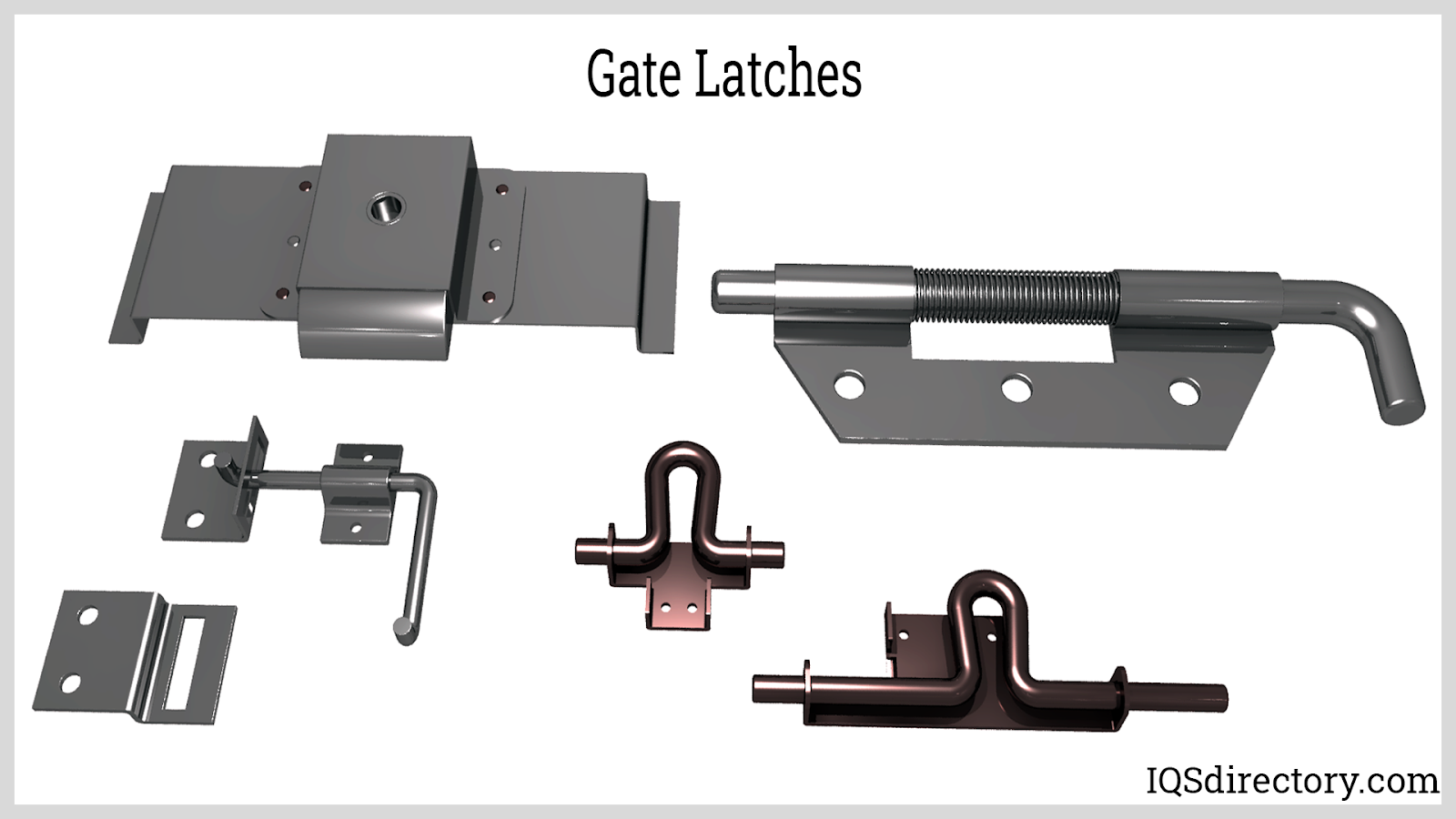

Cane bolt latches are essentially oversized and sturdier versions of barrel bolts. They feature a rod that slides through two holders, commonly used to secure exterior doors and gates in industrial settings. When a gate is shut, the rod inserts into a drilled hole on the driveway surface, ensuring closure. Additional holes may be drilled to hold the gate open as needed. These bolts require manual operation to lock and unlock. By engaging with a floor-mounted hole, they offer enhanced strength and an extra layer of security.

Bolt latches represent one of the most straightforward types of latches. They come in single or double bolt configurations and are commonly employed on doors and gates.

Spring latches, or spring load latches, operate on a straightforward mechanism. When the door is shut, an angled bolt edge interacts with a spring, securing the door. To unlock the latch, users simply rotate the handle, retracting the spring and enabling the door to open easily.

Draw latches, , also known as tension or toggle latches, serve to bring surfaces together and firmly secure them. They typically comprise two plates and a connecting strap or pin, offering versatility for various household and office items such as suitcases, briefcases, trunks, toolboxes, and jewelry boxes. They are also adaptable for use in corners and with hinges. Known by names like pull-down latches, over-center fasteners, or toggle clamps, they find frequent application in electronic enclosures and equipment control panels, ensuring a tight, protective seal against dust and water ingress.

A draw latch consists of two essential components: a catch and a blade. One hook is affixed to a lever, and as the latch engages, these hooks interlock under tension, effectively uniting the secured parts. This tension is generated when the lever is pressed, pulling the drawbar towards the catch, thereby creating a secure closure.

Compression latches, akin to draw latches, establish a snug connection and are frequently employed in applications where a seal between the adjoining components’ edges is necessary.

Paddle latches employ a unique flip-out handle mechanism designed for secure closure and easy opening as needed. These industrial latches are robust and sizable, ideally suited for various transportation applications. They find extensive use in aerospace, automotive, recreational vehicles, railways, marine environments, and off-highway vehicles.

Slam latches engage securely when a door is forcefully closed. Also called push-to-close latches, they feature spring-loaded mechanisms that are sturdier than standard spring latches. Upon door closure, they automatically lock as the cam rises and rotates into place behind the wall. Ideal for high-traffic industrial environments, they ensure doors lock reliably with each closure.

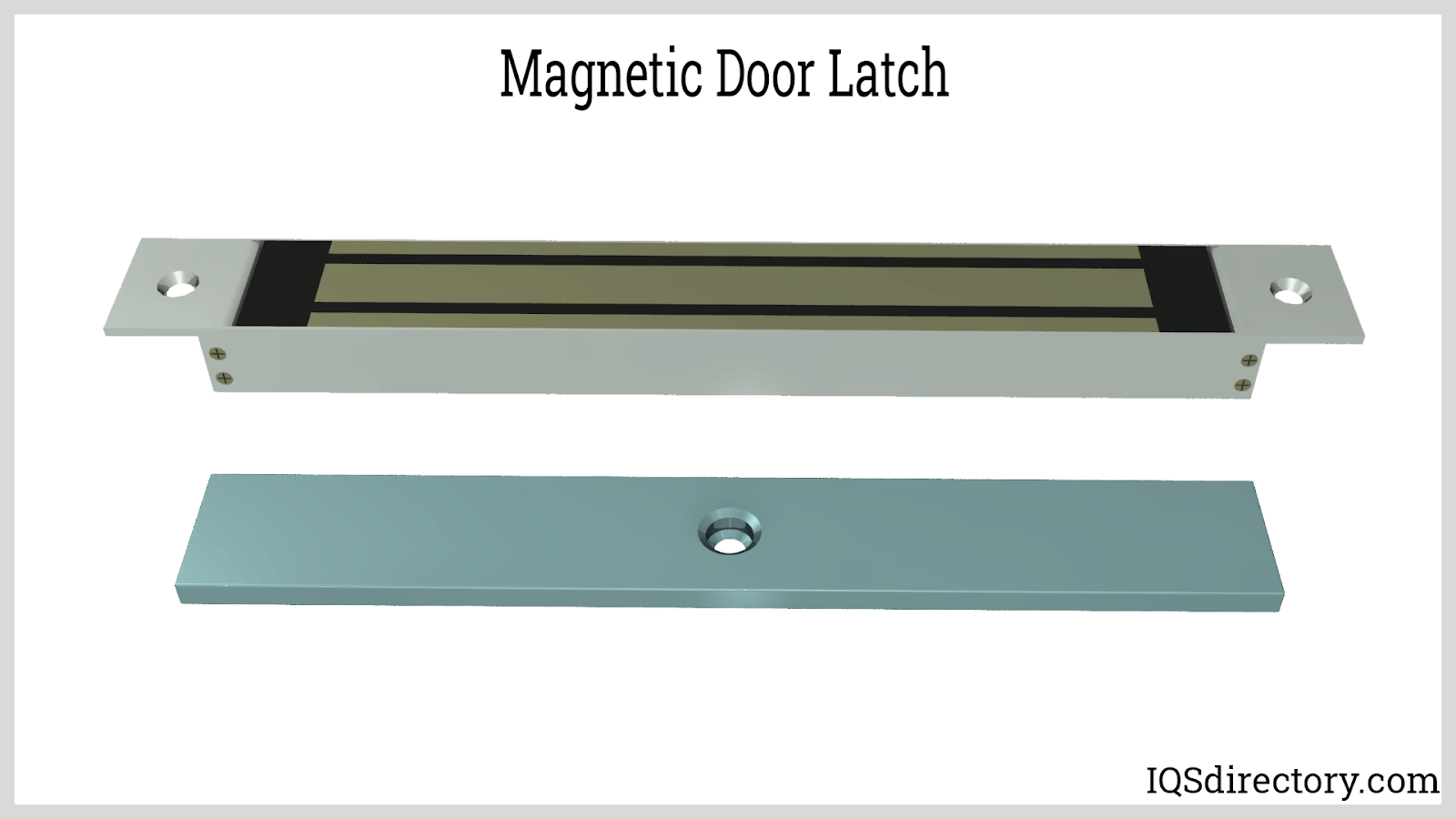

Magnetic latches excel in lightweight applications where mechanical latching isn’t necessary. They find frequent use in drawers, HVAC panels, trucks, and trailers, effectively securing surfaces without the need for locking mechanisms, thus minimizing potential damage to doors and surrounding structures.

SR latches, formally known as set-reset latches, belong to the category of flip-flop circuits. These circuits are designed to maintain two stable states, capable of storing information. By utilizing input and output signals, SR latches effectively secure and release digital electronic systems.

Ring latches, also known as ring gate latches, utilize a prominent ring for easy locking and unlocking. To unlock, one simply lifts and twists the ring; when released, it securely locks back into position. These latches find common use in gardens and backyards, emphasizing ambiance over stringent security measures.

T-handle latches serve to securely fasten doors and lids, ensuring they are closed and locked.

Latch bolts, integral to front door handles, operate with a spring-loaded mechanism positioned at their upper edge and a corresponding strike plate. When the door is pulled shut, the spring-loaded bolt engages with the strike plate, retracting momentarily before extending fully to securely lock the door in place. This ensures the door remains closed once in position.

Rim latches operate by affixing a surface-mounted box and latch mechanism that hooks into the doorframe keeper. Originating from the Colonial era, they are relatively insecure on their own but can be bolstered by pairing them with a hinge and lock assembly for enhanced security.

Industrial latches, known for their robustness and size, are employed in various heavy-duty settings. These latches find application across a spectrum of industries such as marine, railway, automotive, recreational vehicles, aerospace, and off-highway vehicles. This label is reserved for latches capable of withstanding rigorous industrial and commercial demands.

Lever latches are employed to safely lock overhead bins found in vehicles such as RVs and buses.

Gate latches secure the entrances and exits of enclosed areas like agricultural fencing, home fencing, or high-security fencing.

Door latches serve the crucial function of securing doors shut. They come in various types, including spring latches, latch bolts, dead latches, slam latches, and cam locks, each designed for different applications and security needs.

Pawl latches excel in their ability to accommodate a wide range of grip sizes and their versatile application in slide compression fittings. They are particularly ideal for securing electrical switchboards, HVAC enclosures, and various types of industrial machinery and equipment.

Trigger latches are designed with simplicity in mind, offering straightforward functionality. Primarily employed to secure electronic and HVAC enclosures, they operate effectively with a basic mechanism. Depressing the trigger on the lever latch releases the pawl, facilitating door opening. As the lever moves upward concurrently, it doubles as a convenient handle for door operation.

Shutter latches, evolving over time, now commonly are surface-mounted strap hinges, serving the purpose of securing window shutters in place.

Accessories for Latches

Your latches might include a variety of accessories tailored to their specific use. These can range from strike plates, handles, hinges, and springs to bolt springs, anchors, latch sets, installation kits, and tools such as screwdrivers.

Latch Installation

Each latch is unique, making each installation process distinct. However, here are some general guidelines:

Begin by positioning the latch on the edge of the surface to establish your work area. If necessary, mark the spot before removing the latch to clear out the central area and the inner perimeter of the surface using a chisel. Ensure that you chisel to the correct depth. Finally, proceed with installing the latch, which may involve screwing, mounting, or another method. For detailed instructions, refer to your supplier.

Proper Care for Latches

Maintaining your latches is simple yet crucial for longevity and aesthetics. For chrome finishes, regular wiping with a damp cloth suffices. Clear coat finishes benefit from occasional washing using a soft buffing cloth and mild, non-abrasive soap. Bronze finishes require a gentle touch—use a small amount of vegetable oil or a drop of mild household detergent, ensuring careful application due to bronze’s sensitivity.

Standards for Latches

Make sure that whichever latch you choose for your application, it bears the certifications of BHMA (Builders Hardware Manufacturers Association) and ANSI (American National Standards Institute). These stamps guarantee top-notch construction quality and safety.

Additionally, consider other standard requirements based on your specific application and location. For instance, latches may need to meet ADA (Americans with Disabilities Act) standards. To learn more, consult industry experts and relevant governmental authorities.

Things to Consider When Purchasing Latches

Before you buy latches, it’s best to compile a list of your specifications and the latch features you need to consider. This includes determining the number of latches you need, their intended use and performance requirements, the type of surface they’ll be mounted on, any standard specifications to meet, and your timeline and budget constraints.

After compiling all your considerations, the next step is finding the ideal manufacturer. We’ve curated a list of latch manufacturers known for their expertise and reliability. Each has a detailed profile outlining their products and services. Review these profiles against your specifications. Select three or four that closely match your needs. Contact each to discuss your requirements. After these conversations, compare their offerings and decide accordingly.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services