A slam latch is a device that provides the secure closing of cabinets, drawers, and doors. Slam latches are spring-activated and they allow for the fastening of their mechanism without the need for manually selecting it every time. These devices are ideal for sliding doors and utility boxes. Since they are mostly very rugged, they are very suitable for use in a wide variety of settings and applications. Read More…

Cabinet latches are our specialty! We are located in Torrington, CT but we are committed to serving our customers wherever they may need us! All of our products go through extensive and intensive testing to ensure that we are providing our customers with only the best possible products. For more information on what we can do for you visit our website today or get in touch via email or telephone!

Hardware Mfg. supplies stock inventory parts in addition to creating custom components for OEM and resellers. We work with a number of different industries such as agriculture, drug tablet, livestock, truck equipment, conveyors, and more.

At PROTEX® we offer light to heavy-duty fasteners, handles, flush latches, case fittings, bandclamps, catch plates and more. We manufacture a large range of over centre fasteners often known as draw latches/toggle clamps/catches/over centre toggle fasteners.

More Slam Latch Manufacturers

Comprehensive Guide to Slam Latches: Types, Applications, Benefits, and Supplier Selection

In industries where secure closures and high safety standards are paramount—such as construction, transportation, aerospace, manufacturing, and commercial refrigeration—slam latches are critical mechanical devices. Slam latches offer exceptional durability, high cycle performance, and quick, automatic engagement, making them the preferred choice for heavy-duty environments demanding frequent access. Compared to standard spring latches, slam latches are engineered to endure more frequent opening and closing cycles without compromising the locking mechanism or risking premature wear and tear. Whether you need a solution for secure doors, industrial enclosures, or high-traffic access panels, understanding slam latch technology is key to making an informed decision.

What Is a Slam Latch?

A slam latch—sometimes referred to as a slam lock—is a type of spring-loaded mechanical latch that secures doors, gates, hatches, or panels automatically when they are pushed or slammed shut. Unlike traditional latches or draw latches, which require manual engagement or the use of a lever, slam latches use a robust spring mechanism to lock the closure instantly. This provides a seamless user experience and a high level of security and reliability for applications where convenience, speed, and longevity are essential.

The Working Principle of a Slam Latch

Slam latches work by employing a spring mechanism that provides tactile resistance and ensures reliable engagement with every closure. The core components of a slam latch typically include:

- Enclosed spring: Designed for longevity and consistent force, enabling repeated use.

- Sliding pin or bolt: Moves in one direction when the closure is pushed or slammed, guided by a curved notch or cam.

- Notch or curved cam: Allows the pin to slide over and automatically locks it in place once the closure is fully seated.

When a door or panel is closed, the pin glides over the curved cam, compressing the spring. As the door seats into its final position, the spring pushes the pin into the notch, preventing retraction and securely locking the closure. To open, most slam latches feature a lever, knob, or push-button actuator, which retracts the pin and releases the mechanism for easy access. This design ensures fast, hands-free latching, making slam latches ideal for environments where speed and efficiency are crucial.

Key Features of Slam Latches

- Automatic locking—engages instantly upon closure, enhancing operational efficiency and safety.

- High cycle life—robust construction supports frequent usage.

- Vibration-resistant—reduces unintended opening during transit or mechanical vibration.

- Variety of actuation methods—including levers, knobs, push buttons, keys, and paddle mechanisms.

- Multiple mounting options—surface-mount, flush-mount, weld-on, and bolt-on configurations available.

Types of Slam Latches

Slam latches come in a range of designs, each tailored to specific industrial and commercial applications. Selecting the right type depends on your operational needs, installation requirements, and security preferences. Explore the main varieties below:

Single-Point Slam Latch

The single-point slam latch features a straightforward, compact design with a single pin and a simple actuation knob. As a non-locking latch, it is easy to operate and install, making it ideal for situations where fast access is required but keyed security is not a priority. Single-point slam latches are commonly used in equipment enclosures, electrical cabinets, and toolboxes.

Multi-Point Slam Latch

Multi-point slam latches add additional slam bolts to the basic single-point design, providing enhanced security and resistance to prying or accidental opening. With actuation typically managed by a turning knob or T-handle, these latches are preferred for large doors, industrial storage cabinets, and high-security enclosures where distributed locking points are necessary to prevent forced entry.

Push-Button Slam Latch

The push-button slam latch incorporates a tactile button actuator for rapid, one-handed operation. Its curved safety pin design ensures smooth closure, while the push-button mechanism enables quick release. These latches often allow for single-hole installation, reducing labor and tool requirements. Push-button slam latches are highly adaptable to various panel thicknesses and are popular for access panels, service doors, and industrial furniture.

Slam Bolt (Finger-Pull Latch)

The slam bolt, also known as a finger-pull latch, operates on a similar principle to single-point latches but typically requires manual retraction of the bolt for opening. This design is best suited for non-locking doors or hatches where security requirements are low but fast closure is needed. Slam bolt latches are frequently used on utility boxes, equipment hatches, and storage compartments where access is needed from one side only.

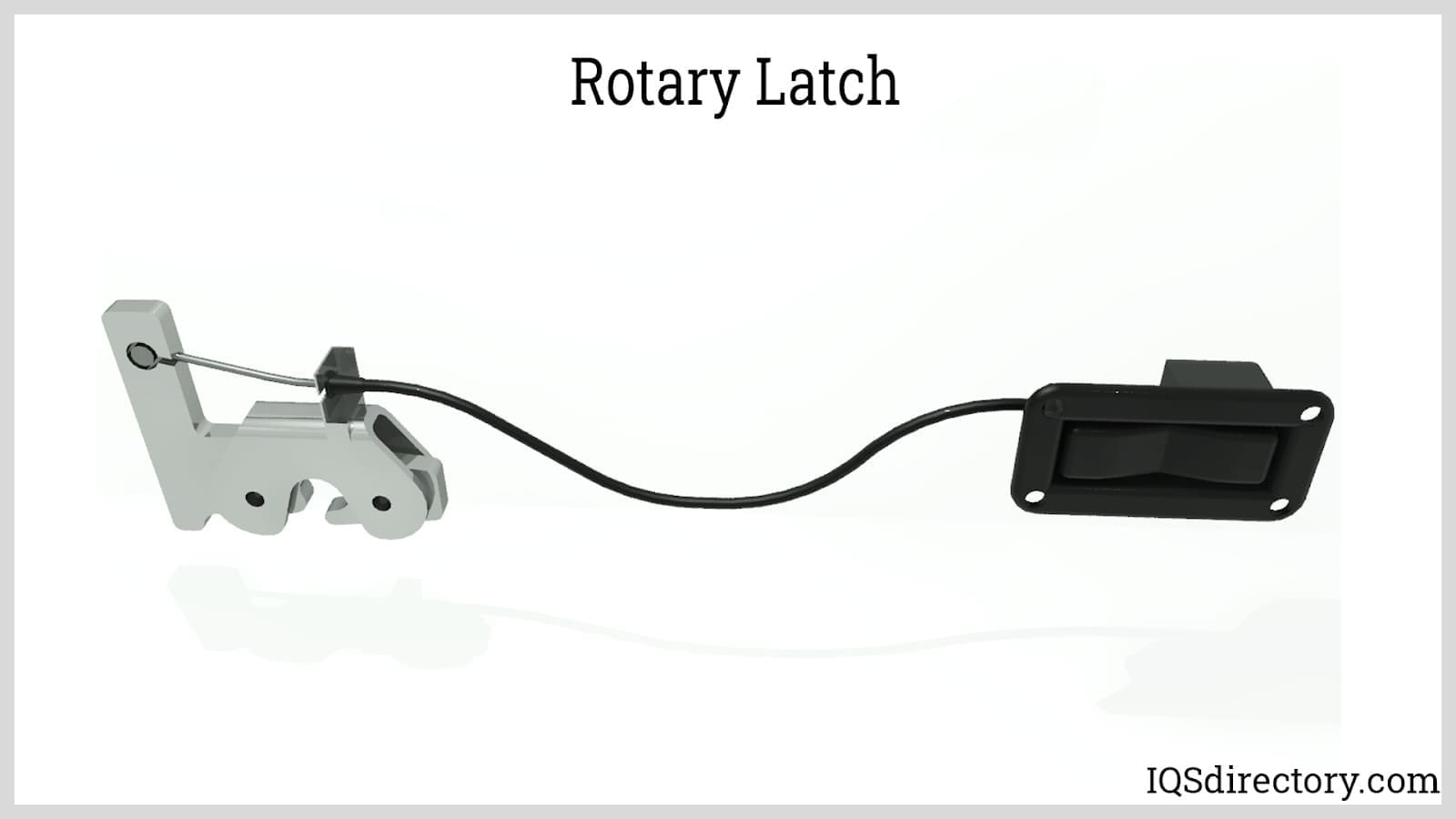

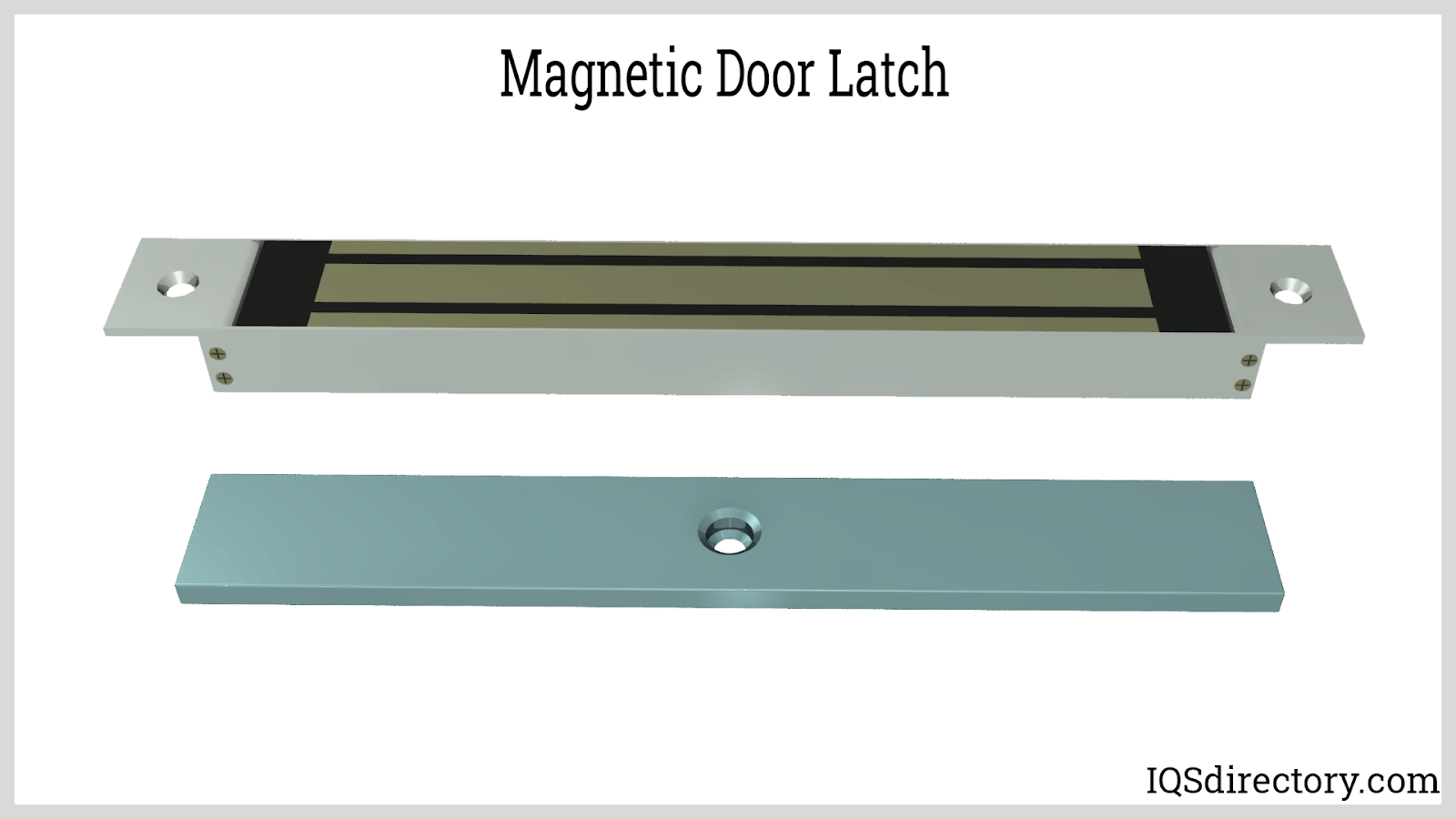

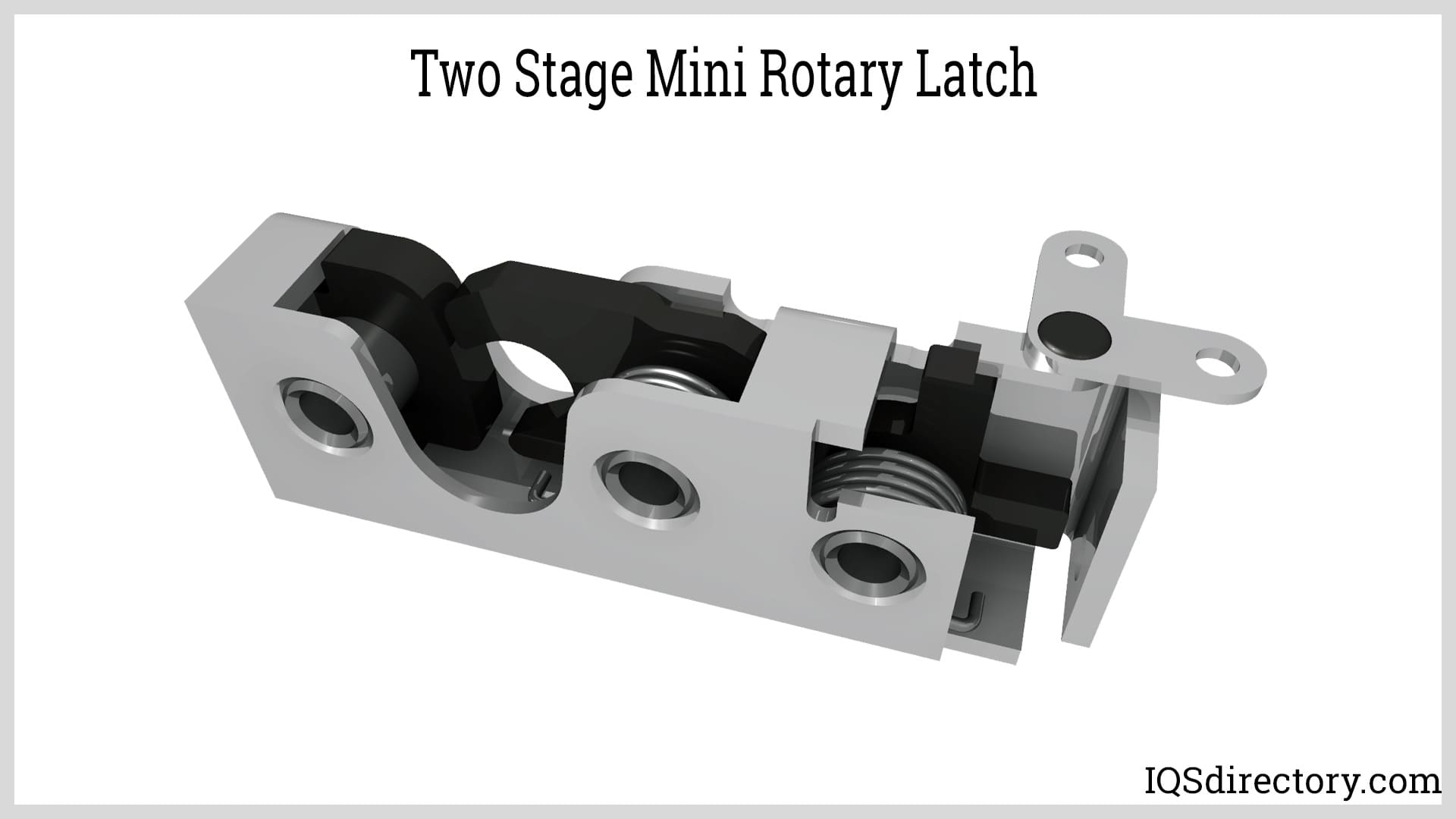

Rotary Slam Latch

The rotary slam latch is one of the most versatile and secure varieties, often featuring a key-locking mechanism for added security. These latches use a rotary cam and can be installed on a wide range of door thicknesses, provided the overall length accommodates the installation. Rotary slam latches are available in both locking and non-locking configurations, with non-locking types typically surface-mounted or welded in place. Common applications include storage units, refrigeration chambers, and vehicle compartments where tamper resistance is critical.

When choosing between locking and non-locking rotary latches, consider whether your application requires key access, remote actuation, or both. Rotary slam latches are increasingly specified for use in automotive, marine, and aerospace sectors due to their reliability and high load capacity.

Paddle Latch (Flush Pull Latch)

The paddle latch, also known as a flush pull latch, is a surface-mounted or flush-mounted slam latch that employs a paddle actuator to retract the pin from the locking element. These two-part latches often feature integrated stops for self-closing doors and are typically installed with threaded fasteners for robust attachment. Paddle latches are popular in commercial vehicles, sliding doors, side panels, and access hatches where low-profile aesthetics and ease of use are valued.

Use Cases and Applications of Slam Latches

Slam latches are engineered for a wide array of demanding applications across multiple industries. Here are some of the most common use cases:

- Refrigeration units and cold storage: Ensures secure, tight closure for walk-in freezers, display fridges, and cold rooms.

- Industrial and commercial cabinets: Provides fast access and automatic re-engagement for electrical cabinets, server racks, and utility enclosures.

- Drawers and toolboxes: Keeps drawers securely closed during movement or transport, reducing the risk of accidental opening or spillage.

- Emergency exit doors: Enables quick, reliable closure and instant re-latching in safety-critical environments.

- Utility boxes and service compartments: Protects sensitive equipment in transit vehicles, RVs, marine vessels, and aircraft.

- Automotive and transportation: Used in passenger vehicles, trucks, buses, and specialty vehicles for securing compartments, access panels, and doors.

- Aerospace and defense: Deployed in aircraft interiors, avionics bays, and military vehicles to ensure rapid, vibration-resistant closure.

- Machine guards and safety enclosures: Adds an extra layer of safety and compliance to industrial machinery and automated systems.

Looking for a slam latch for a specific application? What type of environment or door do you need to secure? Explore our detailed guides on spring latches, draw latches, and more to compare features and performance across latch types.

Benefits and Advantages of Slam Latches

Why choose a slam latch over other closure mechanisms? The advantages of slam latches include:

- Simple, one-handed operation: Allows users to close or secure doors and panels quickly without the need for precise alignment or additional hardware.

- Self-closing and automatic locking: Reduces the risk of doors being left ajar or unsecured, improving safety and operational efficiency.

- Minimal closing force required: The spring-loaded design means doors can be gently pushed or even slammed without risking latch damage.

- Noise and vibration reduction: Many slam latches incorporate dampening features to minimize operational noise and prevent rattle during transit or machine operation.

- Versatile mounting options: Suitable for both sliding and hinged self-closing doors, as well as heavy-duty industrial enclosures.

- Long service life: Engineered for repeated, high-frequency use in demanding environments.

- Customizable security: Available in locking (keyed) and non-locking designs to suit various security requirements.

- Corrosion-resistant materials: Many slam latches are manufactured from stainless steel, zinc alloy, or powder-coated metals for use in harsh or outdoor environments.

Considering a slam latch for your project? How do you prioritize ease of use, durability, and security in your closure hardware? Reach out to suppliers or consult with an engineer to determine the best slam latch design for your specific application.

Decision Factors: How to Choose the Right Slam Latch

Selecting the ideal slam latch for your needs involves evaluating several key criteria. Here are the most important factors to consider:

- Application environment: Is the latch for indoor, outdoor, corrosive, or high-vibration settings?

- Load requirements: What is the expected weight and cycling frequency of the door or panel?

- Security level: Do you need a locking mechanism, or is convenience the priority?

- Mounting style: Should the latch be surface-mounted, flush-mounted, or welded in place?

- Material compatibility: What door thickness and panel material (metal, plastic, composite) will the latch be installed on?

- Aesthetic preferences: Are low-profile or concealed latches preferred for visual appeal?

- Compliance and certification: Does your application require UL, CE, or other safety and quality certifications?

- Budget and lead time: What is your project timeline, and how does price factor into your hardware selection?

Not sure which slam latch is right for you? Try searching: “What type of slam latch is best for heavy-duty vehicle doors?” or “Which slam latch materials offer the most corrosion resistance for marine applications?”

Slam Latch Materials and Finishes

Material selection impacts the longevity, strength, and corrosion resistance of slam latches. Common materials and finishes include:

- Stainless steel: Offers superior corrosion resistance and mechanical strength, ideal for food processing, marine, and outdoor use.

- Zinc alloy: Provides good durability and cost-effectiveness for general industrial applications.

- Powder-coated steel: Adds an extra layer of protection against rust and wear, suitable for high-traffic or exposed environments.

- Plastic or composite: Lightweight and non-conductive options for electronics enclosures and specialized equipment.

Finish options can include chrome plating, black oxide, or custom colors to match OEM requirements or branding standards.

Installation and Maintenance Considerations

Proper installation and regular maintenance are essential for maximizing slam latch performance and lifespan. Best practices include:

- Follow manufacturer instructions for mounting style and hardware selection.

- Ensure alignment between latch and strike plate or receiving notch to prevent misfires or premature wear.

- Lubricate moving parts periodically, especially in harsh environments.

- Inspect for signs of corrosion, fatigue, or mechanical failure, and replace latches as needed.

- Consider using thread-locking compounds or lock washers for high-vibration applications to prevent loosening.

Want step-by-step help? How do you install a slam latch on a steel panel? Read our installation guides or ask our experts for advice on best practices.

Choosing the Right Slam Latch Supplier

To ensure the most beneficial outcome when purchasing slam latches, it’s essential to compare multiple slam latch suppliers and manufacturers. Use our directory of reputable suppliers, each with a detailed business profile highlighting their technical expertise, manufacturing capabilities, and product range. Each listing features a direct contact form, allowing you to request information, technical drawings, or a personalized quote.

Ready to evaluate slam latch vendors? What certifications and industry experience do they offer? Use our patented website previewer to quickly review supplier specialties, then leverage our streamlined RFQ (Request for Quote) form to contact multiple slam latch companies with a single submission. This approach helps you compare pricing, availability, lead times, and customization options side by side.

Frequently Asked Questions About Slam Latches

What are the most common failures of slam latches, and how can they be prevented?

Most failures result from misalignment, excessive wear, or corrosion. Prevent issues by ensuring proper installation, choosing corrosion-resistant materials, and performing periodic maintenance checks. Upgrading to a heavy-duty or sealed design can further improve reliability in harsh settings.

Are slam latches suitable for outdoor or marine environments?

Yes, provided you select models made from stainless steel or corrosion-resistant alloys, with weatherproof seals if necessary. These resist rust, salt, and moisture, making them ideal for marine, transportation, and outdoor enclosures.

Can slam latches be integrated with electronic locking systems?

Some advanced slam latch designs feature provisions for electronic actuation, sensors, or remote release mechanisms. These are commonly used in access control systems, security doors, and high-tech enclosures. Consult with your supplier for integration options.

How do I choose between a locking and non-locking slam latch?

Consider the security requirements of your application. For high-value or safety-critical environments, opt for key-locking or electronic locking slam latches. For rapid access and convenience, non-locking types may suffice.

What customization options are available for slam latches?

Many manufacturers offer customization in terms of size, mounting configuration, finish, actuation style, and branding. Large projects or OEM contracts may also allow for custom materials, load ratings, or integration with other hardware.

Take the Next Step—Find the Ideal Slam Latch for Your Application

Ready to improve safety, efficiency, and reliability with the right slam latch solution? Start by exploring our directory of top slam latch suppliers, reviewing their technical offerings, and requesting a quote for your project requirements. Whether you need high-security locking latches, vibration-resistant designs, or cost-effective solutions for industrial enclosures, our network of experts can guide you to the best fit for your needs.

Have more questions or unique requirements? What industry-specific standards does your application require for latch hardware? Contact us today for expert advice, product comparisons, and access to a wide range of latch technologies engineered for your success.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services